- LIGHTNING ARRESTER

- ISOLATING SWITCH

- INSULATOR

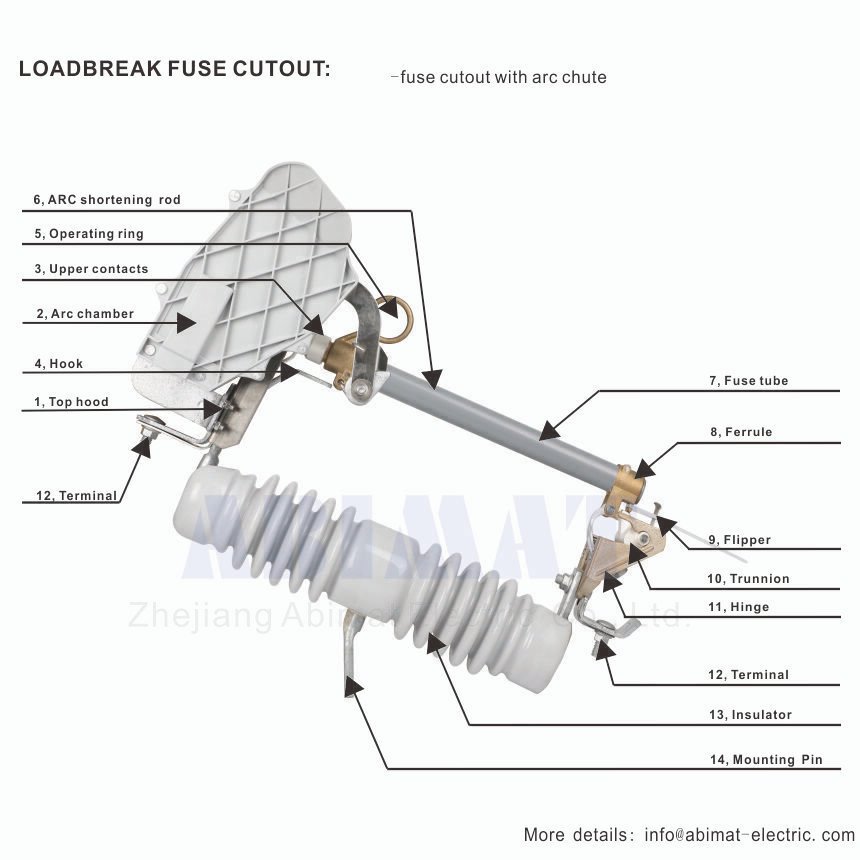

Load Break Fuse Cutout: Ensuring Reliable Power Distribution and Safety

Introduction:

Load break fuse cutouts are critical components in electrical power distribution systems. They play a vital role in protecting equipment and ensuring the safety and reliability of power supply. In this article, we will explore the features, benefits, applications, and technical details of load break fuse cutouts, emphasizing their importance in modern electrical infrastructure.

1. Understanding Load Break Fuse Cutouts:

Load break fuse cutouts are designed to provide a safe and reliable means of interrupting and isolating electrical circuits during load-breaking operations or in the event of a fault. They combine the functions of a fuse and a disconnect switch, allowing for both protection and disconnection of the circuit.

2. Key Features and Benefits:

Overcurrent Protection: Load break fuse cutouts feature a built-in fuse element that responds to overcurrent conditions. These cutouts are typically rated for voltages ranging from 1 kV to 38 kV and current ratings from 100 A to 1,200 A, ensuring compatibility with a wide range of distribution systems.

- Load Breaking Capability: These cutouts are designed to safely interrupt and isolate loads. The operating principle involves using a disconnecting blade to physically separate the contacts and open the circuit. The blade is actuated either manually or by an automated mechanism, allowing for smooth and reliable load breaking operations.

- Fault Isolation: In the event of a fault, load break fuse cutouts provide a reliable means of isolating the affected section of the circuit. Their internal construction includes arc extinguishing chambers, which help to suppress and extinguish the arc that forms during fault conditions. This prevents further damage and ensures uninterrupted power supply to unaffected areas.

- Visible Indication: Many load break fuse cutouts incorporate visible indicators, such as a mechanical flag or a window with colored markers, to provide clear status information. These indicators show the state of the fuse element, allowing maintenance personnel to quickly identify blown fuses and take appropriate action.

- Construction and Materials: Load break fuse cutouts are typically constructed with high-quality insulating materials, such as porcelain or polymer, to provide excellent electrical insulation and mechanical strength. The fuse elements are often made of silver or copper alloys, known for their excellent conductivity and current interruption capabilities.

3. Applications:

Load break fuse cutouts find widespread applications in various sectors, including:

- Distribution networks: They are commonly used in overhead distribution lines to protect transformers, capacitors, and other distribution equipment.

- Industrial installations: Load break fuse cutouts are employed in industrial facilities to safeguard motors, control systems, and machinery.

- Renewable energy systems: They play a crucial role in solar and wind power generation systems, protecting inverters, transformers, and associated components.

4. Installation and Maintenance:

Proper installation and regular maintenance are essential for ensuring the optimal performance of load break fuse cutouts. It is recommended to follow manufacturer guidelines and industry standards during installation. Routine inspections, including checking for signs of degradation, loose connections, and proper fuse element alignment, help ensure their reliable operation.

Conclusion:

Load break fuse cutouts are indispensable components in modern power distribution systems. Their ability to provide reliable overcurrent protection, facilitate load breaking operations, and ensure fault isolation makes them essential for the safety and reliability of electrical infrastructure. By incorporating additional technical details, stakeholders can gain a comprehensive understanding of load break fuse cutouts and make informed decisions when implementing them to optimize power distribution and maintain a robust electrical network.